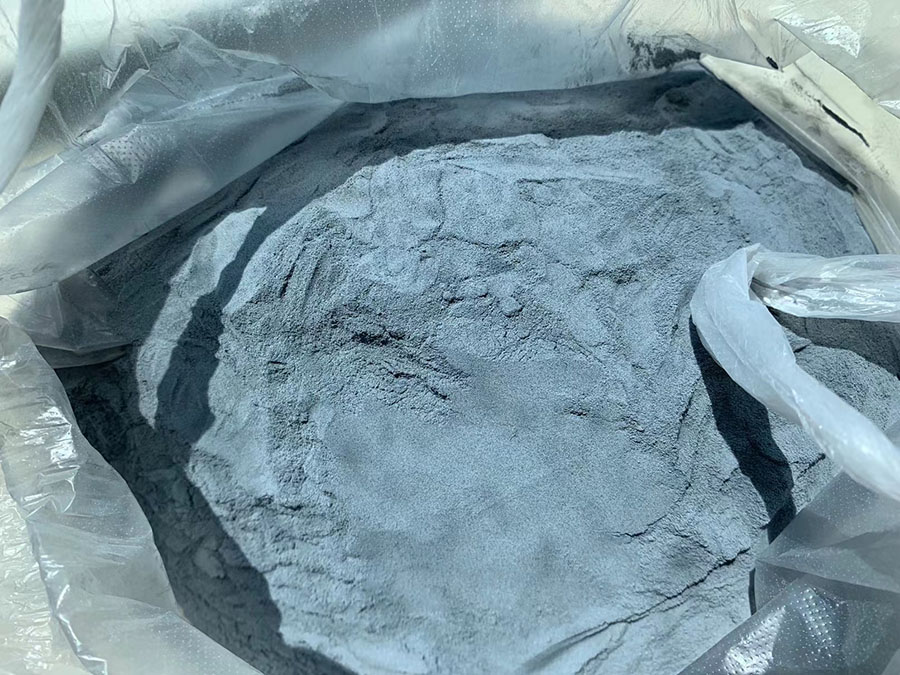

Silica Fume

- Producer:Henan,China

- Customized:Customized logo, customized packaging, or according to your requirements.

- Describe:Silica fume, also known as micro silica, is scientifically named silica fume, which is collected and processed by a special collection device for the smoke and dust that escapes with the exhaust gas during the high-temperature melting of industrial silicon and ferrosilicon in industrial electric furnaces. In the escaping soot, the SiO2 content accounts for about 90% of the total soot, the particle size is very small, and the average particle size is almost nanometer level, so it is called silico

- 24-Hour Sales Hotline:+86 15837207537

- Whatsapp:8615837207537

- Email:info@lsalloy.com

Details:

Description of Silica Fume

Silica fume, also known as micro silica, is scientifically named silica fume, which is collected and processed by a special collection device for the smoke and dust that escapes with the exhaust gas during the high-temperature melting of industrial silicon and ferrosilicon in industrial electric furnaces. In the escaping soot, the SiO2 content accounts for about 90% of the total soot, the particle size is very small, and the average particle size is almost nanometer level, so it is called silicon powder.

Application of Silica Fume

Cement or Concrete Admixture

Microsilica can fill the pores between cement particles, and at the same time form a gel with the hydration product, and react with the alkaline material magnesium oxide to form a gel. Adding an appropriate amount of silica fume to cement-based concrete, mortar and refractory castables can play the following roles:

1. Significantly improve the compression resistance, flexural resistance, impermeability, anti-corrosion, impact resistance and wear resistance.

2. It has the functions of water retention, preventing segregation and bleeding, and greatly reducing the resistance of concrete pumping.

3. Significantly prolong the service life of concrete. Especially in harsh environments such as chloride pollution erosion, sulfate erosion, high humidity, etc., the durability of concrete can be doubled or even several times.

4. Significantly reduce the ground dust of sprayed concrete and castables, and increase the thickness of a single spray layer.

5. It is a necessary component of high-strength concrete, and has been used in engineering applications of C150 concrete.

6. It has about 5 times the effect of cement, and it can reduce costs and improve durability when used in ordinary concrete and low-cement castables.

7. Effectively prevent concrete-alkali-aggregate reaction.

8. Improve the compactness of castable refractories. When it coexists with Al2O3, it is easier to form mullite phase, which enhances its high temperature strength and thermal shock resistance.

9. It has a very strong volcanic ash effect. When mixing concrete, it can undergo secondary hydration reaction with cement hydration product Ca(OH)2 to form a gelled product, fill the cement stone structure, improve the microstructure of the slurry, and increase the Mechanical properties and durability of hardened bodies.

10. Silica fume is amorphous spherical particles, which can improve the rheological properties of concrete.

11. The average particle size of silica fume is relatively small, which has a good filling effect and can be filled in the gaps of cement particles to improve the strength and durability of concrete.

Refractory Additives

High-quality silica fume is mainly used as high-performance refractory castables, prefabricated parts, ladle materials, breathable bricks, self-flowing refractory castables and wet and dry spray materials. In the field of high-temperature ceramics, such as: oxide-bonded silicon carbide products, high-temperature calcium silicate lightweight insulation materials, corundum mullite push plates for induction kilns, high-temperature wear-resistant materials and products, corundum and ceramic products, and Sailong combination Products, etc., the use of silica fume has the characteristics of high fluidity, low water storage capacity, high density and high strength.

Metallurgical Pellet Binder

Micro-silica fume is mixed with water to make pellets and then naturally dried or sintered without additional binder. There are very few impurities in the pellets, which can be returned to the electric furnace as smelting materials.

Dispersant for Chemical Products

In order to prevent the agglomeration of some chemical synthetic powders, micro-silica powder can be used to replace more expensive processing materials, to replace part of the dispersion and isolation and to increase the effect. It is widely used in fine pesticides, fertilizers, fire extinguishing agents and other products.

About the Company

Anyang Lishi Industry uses advanced production technology and precise quality control measures to ensure the high purity and stable quality of each batch of products. Our wollastonite has a fine particle structure and high activity, which can significantly improve the mechanical properties, durability and permeability resistance of concrete and cement products. Anyang Lee's Industry pays attention to scientific research innovation and technological progress. We have a team of professional engineers and R&D personnel to meet the ever-changing market needs through continuous research and development work.

Welcome to your inquiry!

Service Hotline:+86 15837207537 Whatsapp:8615837207537 Email:info@lsalloy.com